Industry News

DECOWELL IO Expanders: Maximizing Efficiency in Industrial Automation

At DECOWELL, we recognize the critical importance of optimizing control cabinet space in today's industrial automation systems. Our advanced IO expander solutions address this challenge effectively, providing complete functionality through intelligent, space-saving designs. The input/output expander units in our RB series embody a significant advancement in compact industrial connectivity, offering outstanding performance while reducing spatial requirements in electrical enclosures.This breakthrough enables manufacturers to scale their automation capabilities while maintaining clean, organized control panel layouts that simplify troubleshooting and maintenance.

Innovative Hot-Swap Technology for Continuous Operation

The DECOWELL hot-swap system represents over five years of focused R&D, resulting in a truly interruption-free replacement process that maintains signal integrity during module exchanges. A defining characteristic of our input/output expander range is the pioneering hot-swap capability. This essential feature enables component replacement during active system operation without interrupting manufacturing workflows. Technicians can exchange specific IO expander modules while maintaining normal system functionality, dramatically decreasing operational interruptions in industrial settings. The integrated module-level diagnostics facilitate rapid fault identification, permitting precise replacements that restore full system capability with maximum efficiency.Our field tests demonstrate the hot-swap system maintains 100% signal continuity during module replacement, a critical advantage for continuous process industries.

Pioneering the Future of Industrial Connectivity

The RB series' breakthrough 12mm profile was achieved through a complete re-engineering of traditional I/O architectures, eliminating redundant space while enhancing thermal management. DECOWELL persistently advances the capabilities of input/output expander technology. Our RB series serves as a prime illustration of our approach to reinventing industrial connections to satisfy the changing demands of contemporary automation systems. By integrating space-optimized configurations with reliable performance and groundbreaking features like hot-swap functionality, we assist manufacturers in maximizing their control panel utilization while ensuring system dependability and effectiveness. For organizations seeking to enhance their industrial network infrastructure with next-generation IO expander solutions, DECOWELL delivers an ideal blend of innovation, quality, and practical engineering knowledge. Explore how our efficient, high-performance modules can revolutionize your automation framework today.

Comprehensive Solutions for Diverse Industrial Needs

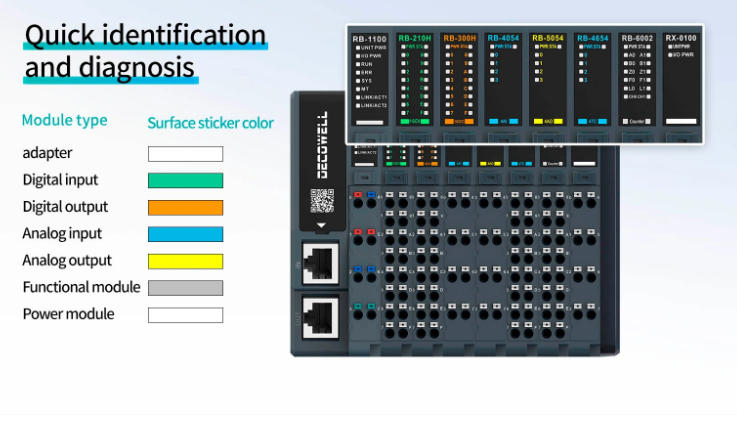

DECOWELL's modular approach delivers unprecedented application flexibility, with over 15 specialized module types covering virtually every industrial signal processing requirement.Our input/output expander offerings cater to a wide spectrum of industrial requirements through specialized module configurations. From digital and analog signal processing to dedicated temperature monitoring and encoder interfaces, we supply solutions for nearly every industrial application scenario. Supporting all major industrial communication protocols including PROFINET, EtherCAT, and EtherNet/IP, our IO expander products ensure seamless integration with existing automation architectures. This adaptability makes our solutions suitable for applications spanning from discrete manufacturing to continuous process control, where diverse signal types and communication standards must operate in harmony.

Engineering Excellence in Compact Design

The DECOWELL RB series IO expander achieves remarkable space efficiency with its ultra-slim 12mm profile, representing a substantial reduction in cabinet space requirements. This streamlined input/output expander design incorporates a three-segment architecture that facilitates terminal removal and simplifies maintenance procedures. The compact form factor maintains uncompromised operational reliability, featuring swift signal response times and consistent data transmission for both input acquisition and output control functions. Our engineering team has meticulously balanced size reduction with performance preservation to deliver these space-optimized solutions.

Intelligent Diagnostics for Proactive Maintenance

Built-in diagnostic capabilities change maintenance from reactive to proactive. Each module continuously monitors its operational status, providing detailed health metrics through standard industrial protocols. This goes beyond simple fault detection - our system tracks performance degradation over time, allowing maintenance teams to schedule replacements during planned downtime. The diagnostic data integrates seamlessly with most industrial SCADA and MES systems, creating a comprehensive view of your automation health.

Streamlined Implementation Process

We've rethought every aspect of the implementation process to minimize deployment time. The tool-less terminal design reduces wiring time by up to 70% compared to traditional I/O systems, while color-coded connectors eliminate installation errors. Field-proven quick-connect mechanisms enable effortless module replacement, while intuitive status LEDs provide instant visual confirmation of proper installation. The unified design language across all module types further simplifies technician training and reduces the learning curve.Our standardized mounting system ensures perfect alignment every time, whether you're installing a single module or an entire rack. These thoughtful design elements combine to deliver a system that's as easy to deploy as it is to maintain, reducing total cost of ownership throughout the product lifecycle.