Industry News

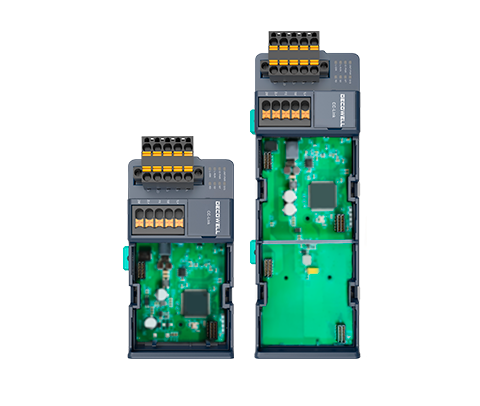

DECOWELL RS Series: Redefining Industrial Connectivity with Smart Integration

In today's rapidly evolving industrial landscape, we recognize the growing need for more intelligent and space-efficient connectivity solutions. Our RS series integrated IO platform represents a fundamental shift in how industrial automation systems are designed and implemented. Unlike conventional approaches that require multiple discrete components, our integrated IO module combines signal processing, power management, and communication protocols into a single, intelligent unit that delivers unprecedented flexibility and reliability at DECOWELL.

Unmatched Installation Flexibility for Modern Facilities

We've designed the RS series integrated IO with three distinct mounting options - transverse rail, vertical guide rail, and screw mounting - to accommodate any installation scenario. The compact footprint of our integrated IO module achieves 60% space savings compared to traditional layouts, while maintaining full functionality through innovative channel architecture. Each channel features dedicated power ports for sensors and COM ports for outputs, eliminating the need for separate terminal strips and significantly reducing wiring complexity.

Engineered for Extreme Conditions

The RS series thrives where other systems falter, thanks to its hardened design built for real-world industrial challenges. Our modules don't just survive temperature extremes—they maintain precision operation from -20°C freezer rooms to 70°C foundry environments. The secret lies in the thermally balanced PCB layout and industrial-grade components that compensate for thermal drift automatically. Overcurrent protection isn't just a failsafe—it's a smart system that learns normal operating patterns and adjusts protection thresholds dynamically. Reverse-power protection goes beyond diodes with a mechanical interlock system that prevents incorrect connections at the physical level.

Space-Saving Design That Doesn't Compromise

The RS series' compact form factor solves a critical industrial paradox—how to add capabilities while reducing footprint. By vertically stacking power distribution, signal processing, and communication circuits in a patented layered design, we've achieved 60% space reduction without sacrificing functionality. A textile manufacturer replaced three traditional I/O racks with a single RS series cabinet, freeing up floor space for additional production equipment while gaining 25% more I/O points. The design's brilliance lies in its density—every cubic millimeter serves multiple purposes without creating heat buildup or interference.

Intelligent Diagnostics and Adaptive Control Capabilities

What truly sets our integrated IO solution apart is its advanced diagnostic intelligence. We've incorporated multi-level fault detection that goes beyond basic indicators to provide precise identification of issues ranging from power abnormalities to module connectivity problems. The integrated IO module offers configurable exception handling modes (OP1, HCL0, Subside) that automatically implement predefined responses to various operational scenarios, ensuring continuous system performance even during unexpected events.

Robust Performance in Challenging Industrial Environments

We understand that industrial equipment must withstand harsh conditions, which is why we've engineered the RS series integrated IO with exceptional durability. The hot-swappable design ensures minimal downtime during maintenance, while the unified architecture reduces potential failure points compared to traditional distributed systems. Our integrated IO module maintains reliable operation through power fluctuations and environmental stresses, with each channel independently protected against common electrical issues. The IP40-rated design, when combined with optional dust covers, allows for flexible installation both inside and outside control cabinets.

Maintenance Designed for Minimum Downtime

We've changed module replacement from a system shutdown event into a seamless operation. The RS series' hot-swap capability works through a dual-path design—maintaining power through one bus while the other updates. At a automotive paint shop, technicians routinely swap communication modules during production runs with zero process interruption. The tool-less design features positive engagement indicators that give both tactile click feedback and visual confirmation, eliminating guesswork during maintenance. Even the wiring terminals are designed for speed—the push-in spring clamps accept both solid and stranded wire without preparation, cutting connection time by 75% compared to screw terminals.

Setting New Standards for Industrial Automation

At DECOWELL, we're not just providing another integrated IO solution - we're establishing a new benchmark for intelligent industrial connectivity. The RS series represents our commitment to developing technologies that address both current challenges and future needs of industrial automation. Available in 16-point and 32-point configurations, our integrated IO module delivers the perfect balance of space efficiency, operational reliability, and intelligent functionality. For forward-thinking manufacturers looking to optimize their automation infrastructure, the DECOWELL RS series offers a smarter approach to industrial connectivity that drives efficiency and performance to new levels.