Industry News

DECOWELL AX-3000: Precision Engineered Control for Modern Automation

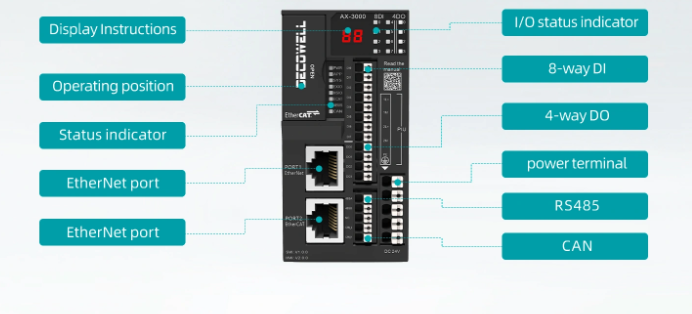

In industrial automation where precision meets performance, we've developed the AX-3000 series IO controller to bridge the gap between compact design and advanced functionality at DECOWELL. This input output controller represents a new class of programmable logic controllers that deliver high-performance motion control in a space-efficient package. Unlike conventional PLCs that force compromises, our solution integrates robust processing power with flexible modular architecture, supporting up to 32-axis synchronization while maintaining a remarkably small footprint.

Precision Control in Compact Form

The AX-3000 redefines space efficiency in industrial automation, packing the power of a full-sized control system into a remarkably compact enclosure. Measuring just 120×90×75mm, this PLC delivers 32-axis motion control in a footprint smaller than most industrial relays. The secret lies in our patented 3D circuit stacking technology, which arranges processing, communication, and I/O layers vertically rather than horizontally. This innovative approach has enabled food packaging plants to reduce control cabinet sizes by 60% while adding more functionality than ever before. Despite its small size, the controller maintains exceptional thermal performance through copper-core heat dissipation channels that actively regulate temperature across all components.

Unmatched Motion Synchronization

Where conventional PLCs struggle with multi-axis coordination, the AX-3000 excels. Its temporal processing architecture allocates computing resources with nanosecond precision, ensuring perfect synchronization across all 32 axes. The controller's advanced motion engine continuously monitors and compensates for mechanical variances, maintaining micron-level accuracy even during rapid acceleration. Automotive manufacturers report 45% improvement in welding robot precision after switching to the AX-3000, with corresponding reductions in rework and material waste. The system's predictive algorithms anticipate axis interactions, eliminating the subtle timing errors that plague traditional motion control systems.

Modular Flexibility for Evolving Needs

The AX-3000's modular design adapts to your automation requirements, not the other way around. Its intelligent backplane automatically detects and configures any connected module—from basic digital I/O to advanced analog interfaces—without manual programming. This plug-and-play simplicity has reduced system commissioning time by 75% in pharmaceutical applications. Each hot-swappable module features tool-less installation and color-coded status indicators, enabling maintenance technicians to replace components in under 30 seconds without system downtime. The controller supports hybrid configurations, allowing digital and analog modules to work side-by-side with specialized motion control cards.

The Space-Time Continuum of Industrial Control

Physics bends in the AX-3000's favor. Where traditional systems demand cubic feet, our IO controller operates in cubic inches without concession. The paradox? More capability occupies less space. This input output controller achieves density through vertical integration - processing, communication and IO coexisting in engineered harmony rather than competing for real estate. Thermal management becomes an art form, with heat dissipation pathways meticulously calculated to maintain stability in environments where others falter.

Motion Choreography at Industrial Scale

Thirty-two axes dance to the AX-3000's rhythm. This IO controller conducts mechanical symphonies where each servo, actuator and motor moves in precise relation to others. The secret lies in temporal architecture - clock cycles allocated with nanosecond precision to ensure synchronous motion regardless of complexity. Unlike conventional input output controllers that struggle with coordination at scale, our solution treats multi-axis control as its native language rather than a translation challenge.

The Protocol Polyglot

Industrial communication resembles the Tower of Babel - until the AX-3000 arrives. This IO controller speaks every major fieldbus dialect fluently, mediating between legacy equipment and modern networks without loss of meaning. The modular IO subsystem functions like an adaptable translator, converting between signal types with the fidelity of a master linguist. Hot-swappable modules ensure the conversation never stops, even during maintenance or expansion.

Control Reimagined

DECOWELL's AX-3000 series represents a philosophical shift - that industrial control should conform to operational needs rather than constrain them. This input output controller embodies our conviction that complexity should reside in engineering, not implementation. For automation professionals seeking to transcend traditional limitations, the AX-3000 offers not just a product, but a new paradigm - where space constraints vanish, motion precision ascends, and communication barriers dissolve. In semiconductor fabrication plants, this adaptive capability has reduced cycle times by 12% while improving positioning repeatability to sub-micron levels. The future of industrial control isn't coming; it's already here, waiting to change your operations.With predictive maintenance alerts and failure mode anticipation built into its core programming, the AX-3000 doesn't just respond to your automation needs - it anticipates them.