Industry News

The Future of Digital I/O Modules in Smart Manufacturing Environments

At DECOWELL, we are keenly aware of the transformative impact that digital I/O modules are having on the landscape of smart manufacturing. As industries strive for greater efficiency, flexibility, and connectivity, digital input and output solutions are becoming increasingly critical. This article aims to explore the future of digital I/O technology in smart manufacturing environments and how it can shape operational practices.

The Importance of Digital I/O in Smart Manufacturing

Digital I/O modules serve as the critical interface between various system components in a manufacturing setup. They facilitate the communication of data between sensors, controllers, and actuators, enabling real-time monitoring and control of manufacturing processes. As we move toward more automated and interconnected production environments, the role of digital input and output devices becomes even more pronounced.

Our experience at DECOWELL shows that the integration of digital I/O modules enhances operational efficiency. These devices allow for precise control over machinery and processes, reducing the likelihood of errors that can lead to costly downtime. In a smart manufacturing environment, where every second counts, the ability to gather and act on data instantaneously is invaluable. This capability not only improves productivity but also enhances quality control, ensuring that products meet the highest standards.

Innovations Driving the Future of Digital I/O

The future of digital I/O modules is poised for significant advancements, driven by several key innovations. One such trend is the integration of IoT capabilities into digital input and output systems. As manufacturers adopt IoT technologies, the ability to connect digital I/O devices to cloud-based platforms will enable more sophisticated data analytics and remote monitoring.

Through IoT integration, digital I/O modules can transmit valuable data to centralized systems, allowing for real-time adjustments and predictive maintenance. This capability reduces the risk of unexpected failures and enhances overall system reliability. At DECOWELL, we see this trend as a game-changer for smart manufacturing environments, enabling businesses to operate with greater agility and responsiveness.

Additionally, we anticipate advancements in the miniaturization and modularity of digital I/O devices. Compact, modular designs will allow manufacturers to customize their systems to suit specific operational needs, leading to enhanced flexibility in production setups. This adaptability is crucial in today’s fast-paced manufacturing landscape, where requirements can change rapidly.

Furthermore, the development of more robust digital I/O modules with improved diagnostic features will significantly enhance operational reliability. These advancements will enable quicker identification of issues, such as wiring faults or sensor malfunctions, minimizing downtime and streamlining maintenance processes. At DECOWELL, we are committed to innovating in this space, ensuring that our digital I/O solutions are equipped with the necessary features to support modern manufacturing demands.

Challenges and Considerations

While the future of digital I/O modules in smart manufacturing is promising, it is not without challenges. One significant hurdle is the need for compatibility among various devices and systems. As manufacturers adopt new technologies, ensuring that digital input and output devices can communicate effectively with existing infrastructure is crucial. This requires a concerted effort to develop standardized protocols and interfaces that facilitate integration.

Cybersecurity is another critical consideration. As digital I/O modules become increasingly connected, the risk of cyber threats grows. Manufacturers must prioritize security measures to protect their systems and sensitive data from potential breaches. At DECOWELL, we recognize the importance of building secure digital I/O solutions that prioritize both functionality and safety.

Additionally, workforce training is essential. As digital I/O technology evolves, employees must be equipped with the skills to manage and operate these advanced systems. Investing in training programs will ensure that manufacturers can fully leverage the benefits of digital input and output technologies.

Conclusion

In conclusion, the future of digital I/O modules in smart manufacturing environments is bright and filled with potential. At DECOWELL, we believe that these technologies will play a crucial role in driving operational efficiency, enhancing flexibility, and enabling data-driven decision-making. As we continue to innovate and refine our digital input and output solutions, we remain committed to helping manufacturers navigate the complexities of modern production environments.

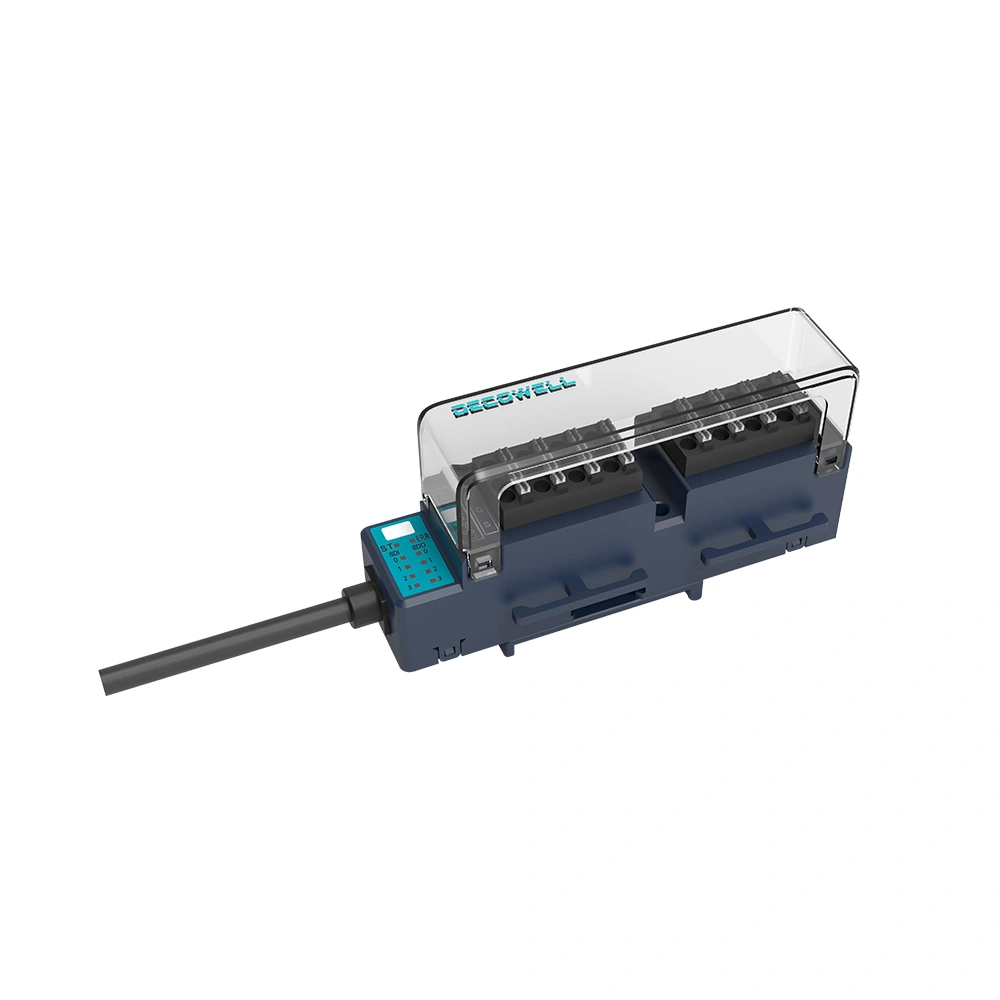

With the introduction of advanced features such as discrete provisioning modules, we aim to enhance wiring layout flexibility and improve interference immunity. Our LS products utilize power carrier technology to simplify wiring and reduce man-hours while providing essential diagnostic functions. This commitment to excellence positions DECOWELL as a leader in the digital I/O space, ready to support the evolving needs of smart manufacturing.